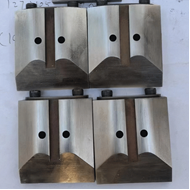

Glue Nozzle

Purpose: Suitable for fully automatic gluing machines.

Product Advantages: Corrosion-resistant, wear-resistant, uniform coating, one-time molding, three glass and two chambers.

Glue Nozzle

Usage: Suitable for a fully automatic gluing machine in insulating glass equipment.

The glue nozzle in the gluing machine of insulating glass equipment is a critical component used to evenly apply adhesive onto the glass frame. It is located at the end of the gluing machine and is responsible for conveying adhesive from the adhesive supply system onto the glass frame.

Here is an introduction to the glue nozzle in the gluing machine of insulating glass equipment:

1. Structure and Material: Glue nozzles are typically made from corrosion-resistant materials, such as stainless steel. They generally consist of a body, a nozzle, and an adhesive outlet. The body is connected to the adhesive delivery pipeline of the gluing machine, the nozzle is where the adhesive is sprayed, and the adhesive outlet is the part that controls the flow and uniformity of the adhesive.

2. Working Principle: When the gluing machine is in operation, adhesive flows through the adhesive delivery pipeline into the body of the glue nozzle. Through the nozzle of the glue nozzle, the adhesive is evenly sprayed onto the glass frame. The adhesive outlet can control the flow and uniformity of the adhesive by adjusting the opening. The working principle of the glue nozzle ensures that adhesive is precisely applied onto the glass frame, ensuring uniformity and quality of the adhesive.

3. Cleaning and Maintenance: After a period of use, the glue nozzle can become sticky due to the curing of the adhesive and requires cleaning and maintenance. During cleaning, the glue nozzle can be removed from the gluing machine and soaked in clean water for some time. Then, a brush and detergent can be used to scrub away the adhesive residues adhering to the nozzle and adhesive outlet. After cleaning, thoroughly rinse the nozzle to ensure there are no adhesive residues left.

4. Maintenance: To ensure the proper functioning of the glue nozzle, it is recommended to regularly inspect its wear and tear. If severe wear or clogging is detected, replace or repair the glue nozzle promptly. Additionally, lubricate the moving parts of the nozzle regularly and check for loose components.

It's important to note that when cleaning and maintaining the glue nozzle, ensure that the equipment is in a stopped and safe state. If unsure about the process or if there are any uncertainties, consider contacting the equipment manufacturer or seeking assistance from a professional technician.