Fully Automatic Insulating Glass Production Line 2025

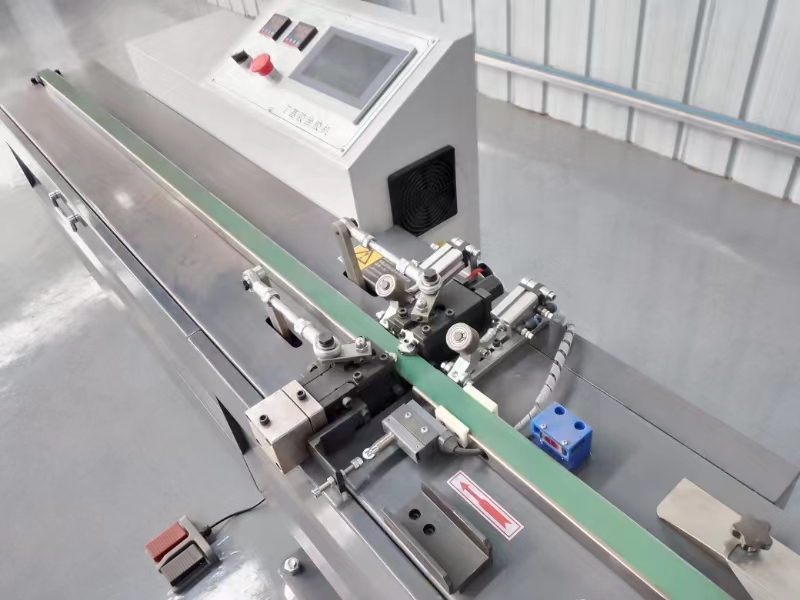

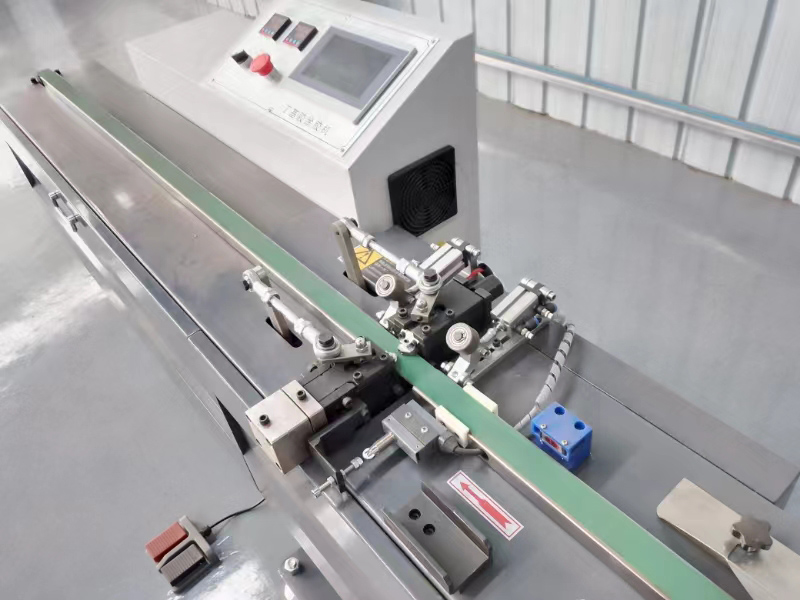

The framework section structure is precision-manufactured using industrial profiles to ensure accuracy and error-free performance. It can be easily adjusted to meet the customer's specific size requirements. The closing mechanism employs a servo closing device with a maintenance-free motor. The crossbeam motor is equipped with a brake, which can achieve 90-degree right-angle positioning to ensure closing accuracy without error or misalignment.

Equipment features:

1. The automatic insulating glass production line belongs to the miniaturization and large-scale design, which makes the equipment suitable for more enterprise production needs.

2. The fully automatic insulating glass production line is made of imported materials, ensuring reliable quality and strong durability.

3. The computerized automation programming control of the fully automatic insulating glass production line allows for remote control and the production of various insulating glass products, including double-layer insulating glass, triple-layer insulating glass, coated insulating glass, and tempered insulating glass.

4. The equipment is equipped with automatic recognition functions, capable of automatically identifying coated glass and LOW-E glass, among others.

5. The cleaning machine and water tank are entirely made of corrosion-resistant stainless steel, ensuring excellent waterproof performance, safety, hygiene, and a long equipment lifespan.

6. The drying section employs double drying, double circulating hot air, and double water absorption to ensure the cleaning effect of the glass, reduce noise, and includes features such as air door, external circulation, and sound insulation for the fan.

7. The equipment uses fully imported low-voltage electrical appliances, sensors, PLC, and other components, ensuring safety, reliability, and a long lifespan.

8. It adopts a touchscreen human-machine interface for easy operation, and it can automatically diagnose equipment failures, demonstrating a high level of automation.

9. Each section of the production line's conveying parts is equipped with parking and buffering functions to prevent glass collisions and effectively reduce wear on the glass transport wheels.

Main Features of Automatic Insulating Glass Production Line

Automation and Precision Control

The production line is equipped with advanced automation systems, including automatic coating inspection, automatic adjustment of air knife width and automatic measurement of glass thickness, to ensure the efficiency and precision of the production process.

The washing and drying sections are made of stainless steel, equipped with soft brushes and new air knives, as well as automatic temperature control and water replenishment systems to ensure the quality and efficiency of glass washing.

Optimised structure and ease of operation

The inspection and installation part adopts double beam structure, which is convenient for operators to inspect and wipe the glass and improve the working efficiency.

The design optimisation of the transfer section and unloading section makes the loading, storing and transferring of glass smoother, reduces manual intervention and improves the overall operation efficiency of the production line.

Quality assurance and environmental friendliness

The design of the production line takes into account product quality assurance, such as the use of high-quality stainless steel materials to prevent corrosion and the adoption of a European-standard noise cancellation system to reduce noise pollution.

Automated production processes and precise control systems ensure that each piece of insulating glass meets high quality standards while reducing energy consumption and environmental impact.

Main Parameters:

Model | 2025 |

Power | 380V 50Hz 18kw |

Maximum Glass Processing Size | 2000*2500mm |

Minimum Glass Processing Size | 480*280mm |

Air Pressure | 0.8m³/min 0.6-0.8Mpa |

Glass Cleaning Thickness | 3-30mm |

Glass Conveyor Speed | 0-50m/min |

Maximum Insulating Glass Thickness | ≤80mm |

Glass Cleaning Speed | 2-15m/min |

Overall Dimensions | 22000*2000*2800mm |