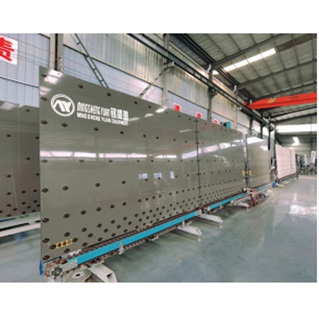

Fully Automatic Insulating Glass Sealing Line 30 Series

1. This system is equipped with a pressing device to ensure safer glass movement during conveying and gluing processes.

2. It can use a single glue supply system or two glue supply systems, allowing for switching between them or using two types of glue (optional).

3. The glue head alignment mechanism allows for adjustments to the glue head based on the thickness of the glass, ensuring that the glue nozzle remains in the center of the cavity, thus achieving better gluing results regardless of the glass thickness.

Equipment Features:

1. Economical, easy to maintain, suitable for medium-sized enterprises and window and door companies.

2. Part of the glass size connects the production line, automatically completing the gluing process with simple operation.

3. Standardized design for increased convenience in maintenance.

4. Human-machine interface with an operation interface designed with simplified thinking, making it straightforward.

5. When glass edges are neatly aligned, the applied sealant is full, without air lines, corners are solid, and all four sides have a smooth surface, eliminating the need for corner corrections.

6. Zero height standardization ensures long-term stable equipment use.

7. The special mixer structure is easy to disassemble and clean, and the mixer core is not easily damaged, reducing operating costs.

8. Can apply sealant to double-pane single cavity, triple-pane double cavity, quadruple-pane triple cavity insulating glass.

9. The conveying load-bearing structure has a high load-bearing capacity and is durable.

10. Unique automatic glue quantity alarm device.

11. The gluing line can store up to two fully coated glass pieces and one waiting glass piece. If the interval between glasses is long (more than five minutes), the gluing machine pauses work. The timed glue discharge function needs to be activated to prevent mixed glue from clogging the mixer.

12. After completing the work, the machine head will automatically discharge white glue. If the set time is too short, it can be modified in the editing function screen.

13. The machine has an automatic cleaning function and automatic glue discharge function.

14. Optional shapes for irregular glass: semi-circular, triangular, rectangular, trapezoidal, straight semi-circular, polygon, etc.

Main Parameters:

Model | 3030 | 3035 | 3050 |

Power | 380V 50HZ 10kw | 380V 50HZ 12kw | 380V 50HZ 15kw |

Maximum Glass Size | 3000*3000mm | 3000*3500mm | 3000*5000mm |

Minimum Glass Size | 300*400mm | ||

Glass Thickness | 12-45mm | ||

Sealant Supply Pressure | <350kg/c㎡ | ||

Sealing Width | 6-24mm | ||

Sealing Depth | 2-15mm | ||

Sealing Speed | 5-32m/min | 5-30m/min | 5-25m/min |

Dimensions | 12000*3500*3400mm | 13500*3500*3400mm | 15500*3500*3400mm |