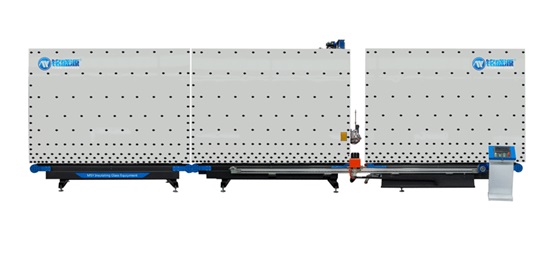

Glass Sealing robot 20 Series

Glued edge is full of airless line, the corner is full, and the surface of the four sides is flat without trimming the corner.The plate is flat, the transfer glass is easy to feed, the glue table vertical synchronous belt holds the transfer glass, so that the glass transfer is smooth, the positioning is accurate, and the glass edge is clean.

All parts are highly standardized to ensure long-term stable use of the equipment.

Equipment features:

1. For switching use of glue system, or switching use of two kinds of glue (optional).

2. The third section can be pre-stored glass to improve production efficiency.

3. Adopt imported brands of low-voltage electrical appliances, pneumatic components, guide screw, sensors, PLC and other components, safe and reliable long life.

4. High automation, high efficiency, suitable for glass deep processing enterprises.

5. Simple interface, easy to use.

6. Glued edge is full of airless line, the corner is full, and the surface of the four sides is flat without trimming the corner.

7. The plate is flat, the transfer glass is easy to feed, the glue table vertical synchronous belt holds the transfer glass, so that the glass transfer is smooth, the positioning is accurate, and the glass edge is clean.

8. All parts are highly standardized to ensure long-term stable use of the equipment.

Equipment parameters:

★ Minimum glass size: 300×400mm

★ Maximum glass size: 2000*2500mm

★ Glass thickness range: 12-45mm

★ Insulating glass thickness: 12-60mm

★ Gluing speed: 5-40 m/min

★ Glue width: 6-24mm

★ Glue depth: 2-15mm

★ Transmission speed: 0-48 m/min

★ Power: 13KW

★ Air source: 0.5-0.8mpa

★ Working height: 520mm