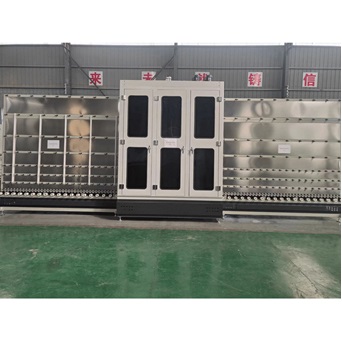

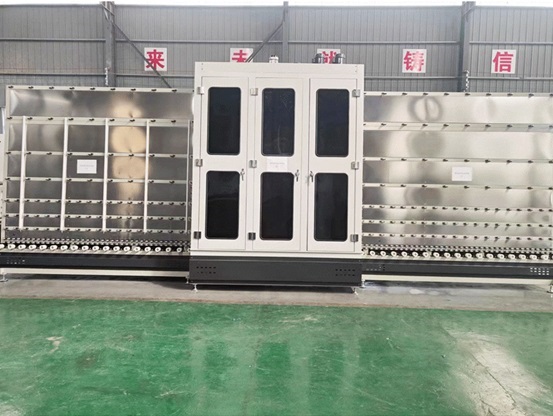

Fully Automatic Vertical Cleaning Machine 20 Series

The cleaning chamber and drying chamber housing are made entirely of stainless steel.

Surface of protective panels treated with baked enamel spray, providing an attractive appearance and durability.

Uses well-known domestic and international brand low-voltage electrical components and sensors for reliability and a long service life.

Equipment Features:

1. This machine is mainly used for the cleaning and pre-treatment of processed insulating glass, tempered glass, and flat glass.

2. It features high production efficiency, safety, reliability, and ease of maintenance.

3. Brush spacing is adjustable, and the brushes are gear-driven, ensuring low noise.

4. Made of stainless steel and other corrosion-resistant materials, it has excellent waterproof performance, safety, hygiene, and a long equipment lifespan.

5. Uses well-known domestic and international brands for low-voltage electrical components and sensors, ensuring safety, reliability, and a long lifespan.

6. The protective plate surface undergoes paint spraying treatment, providing an aesthetically pleasing appearance and durability.

7. The drying section implements double drying, double-circulating hot air, double water extrusion, and double water scraping to ensure effective glass cleaning, reduce noise, and the fan is equipped with air doors, external circulation, and sound insulation functions.

8. The glass cleaning speed can be variable frequency adjusted according to customer process requirements.

9. Buttons are concentrated on the operating interface, making it simple and convenient to use.

10. Suitable for cleaning and processing both insulating glass and ordinary flat glass.

Machine Characteristics:

The cleaning section consists of a cleaning chamber and a drying chamber. The cleaning chamber is composed of three sets of brushes, six sets of conveying rollers, and two sets of water-absorbing rollers. The brushes can clean coated glass, LOW-E glass, and irregular glass. The conveying rollers can automatically open based on the glass thickness. The drying chamber consists of two sets of drying units to effectively blow off the water on the glass.

Main Parameters:

Model | 2025 | 2030 | 2535 |

Power | 380V 50HZ 14KW | 380V 50HZ 15KW | 380V 50HZ 18.5KW |

Maximum Glass Processing Size | 2000*2500mm | 2000*3000mm | 2500*3500mm |

Minimum Glass Processing Size | 480*280mm | ||

Glass Cleaning Thickness | 3-30mm | ||

Glass Conveyor Speed | 0-50m/min | ||

Glass Cleaning Speed | 2-15m/min | 2-12m/min | 2-10m/min |

Overall Dimensions | 7400*2000*3000mm | 8500*2000*3000mm | 9500*2000*3400mm |