Fully Automatic Insulating Glass Panel Inflating Line 2840

1. It automatically displays the inflation status, with a well-designed mechanical system that makes inflation more convenient.

2. The conveying section adopts a double-beam non-marking design, replacing the friction marks caused by glass and rollers during glass transportation. This eliminates the need for rework and significantly improves production efficiency.

3. The characteristics of inflation: sound insulation, heat insulation, sun shading, anti-fogging, reducing glass self-explosion rate, prolonging the lifespan of doors and windows, and enhancing their durability. Due to the higher density of argon gas compared to air, it can prevent glass from inward suction, enhance wind pressure resistance, improve insulation performance, enhance glass safety, and extend the lifespan of molecular sieves, among other benefits!

Equipment Features:

1. Full-process PLC control, frequency conversion control, touchscreen human-machine interface.

2. The feeding section uses universal wheels for easy use of the mechanical arm to load glass, and is equipped with automatic glass height detection with seamless connection to sections 03 and 04.

3. The input section has a coating detection device, ensuring stable and reliable detection.

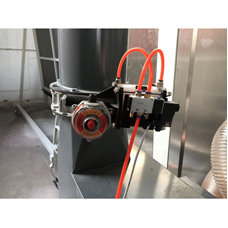

4. The gas-filling and pressing machine adopts four-axis servo linkage, integrating lamination, pressing, and inflation functions, ensuring that the argon content in insulating glass is ≥85%.

5. High-power, high-wind-pressure fan, aluminum alloy air knife for fast drying.

6. The conveying and frame placing sections feature hollow and traceless design, with the upper crossbeam supporting glass transport to avoid glass marks. The frame placing section is equipped with lifting platforms in the front and rear for convenient use with large frames. The equipment is designed for user-friendliness, with rear access doors for maintenance.

7. Aluminum frame positioning uses industrial profiles with functions such as 90° right-angle positioning and adjustability.

8. External lamination is hydraulically controlled for smooth and reliable operation.

9. Brushes use imported materials, capable of cleaning coated glass, LOW-E glass, etc.

10. Capable of producing extra-long, large, three-layer, and irregular insulating glass.

11. The cleaning machine and water tank are entirely made of stainless steel and corrosion-resistant materials, providing excellent waterproof performance, safety, hygiene, and a long equipment lifespan.

12. The cleaning air knife can automatically adjust according to the glass thickness.

13. Each section of the production line's conveying parts features detection functions to prevent glass collisions and effectively reduce wear on glass transport wheels.

14. The drying section implements dual air knives and double-circulating hot air to ensure effective glass drying, reduce noise, and the fan has sound insulation functionality.

Main Parameters:

Model | 2840 |

Power | 380V 50HZ 30KW |

Maximum Glass Processing Size | 2800*4000mm |

Minimum Glass Processing Size | 480*280mm |

Air Pressure | 0.8-1.0Mpa |

Glass Cleaning Thickness | 3-30mm |

Glass Conveyor Speed | 0-50m/min |

Maximum Insulating Glass Thickness | ≤80mm |

Glass Cleaning Speed | 6-9m/min |

Inflation Time | 3-5s |

Ambient Temperature | 7-50℃ |

Overall Dimensions | 28000*2800*3700mm |