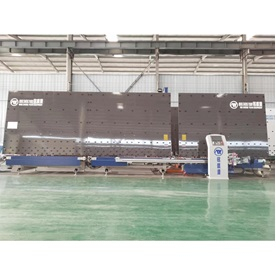

Fully Automatic Vertical Laminating Machine

1. The motor adopts dual oil cylinders and is equipped with large-volume rubber steel, which can load 14L butyl rubber at one time.

2. This machine is a pressure-relief-free coating machine with adjustable speed. The transmission pressure wheel and glue valve automatically operate according to the set program.

3. Advanced gas-liquid boosting system, uniform and stable pressure

Device Features:

1. Dual-sided and single-sided film application capabilities.

2. Various parameters are adjustable, and all actions can be manually operated and display real-time feedback on the HMI (Human-Machine Interface).

3. The operating interface and debugging include manual, automatic, and pause functions.

4. Operation and maintenance require two-level password authorization (operators cannot adjust parameters).

5. Protective film with a layered design, allowing flexible combinations of film sizes to save on film costs.

6. Fault alarm function and a piece count feature.

7. Rolling blade for film cutting, with automatic pressure control to prevent scratching of glass.

8. Three-sided film cutting function, with the white space width adjustable separately in the HMI.

9. Bottom white space reserved during film installation.

10. Control cabinet configured with cooling fans for heat dissipation.

Main Parameters:

Power Supply | 380V50hz |

Air Pressure | 0.5-0.8Mpa |

Minimum Glass Size | 300*600mm |

Maximum Glass Size | 2000*3500mm |

Adaptable Glass Thickness | 4-60mm |

Film Application Speed | 4-20m/min |

Overall Dimensions | 6720*1410*2890mm |