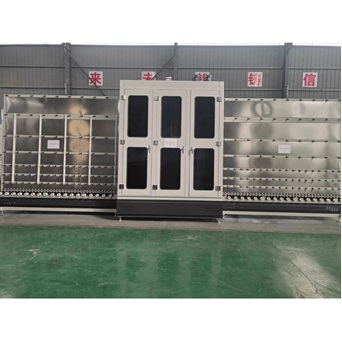

Four Edge Glass Grinding Machine

Man-machine interface is easy to use and friendly. The operator only needs to select the preset processing parameter table according to the glass thickness, load the piece, and start the equipment, and the processing process does not require human intervention.The transmission components and guide rails are equipped with well-protected protective covers and warning signs to avoid equipment damage caused by accidental injury and foreign body falling.

Equipment features:

1. The machine is equipped with three beams and four grinding head groups, each grinding head group is equipped with two and three bottom edge grinding wheels, which is suitable for rough grinding chamfering and bottom edge processing of building hollow and door and window glass.

2. Easy to operate, can automatically adapt to the change of glass length and width, loose processing efficiency close to the whole processing efficiency

3. The conveying part is carried by rubber roller, which has stable conveying and long service life.

4. The water tray, sink, water tank, guard, etc. in contact with water are made of stainless steel, with superior rust prevention performance.

5. The conveying adopts 6 servo stages, and the maximum conveying speed of the discharge section is 50m/min, so as to improve the processing efficiency and shorten the glass spacing as much as possible.

6. The beam adopts national standard profile welding, post-welding annealing treatment, gantry machining center processing, and the guide rail adopts Taiwan TBI brand to ensure high speed, quiet and service life when the grinding head group processes glass.

7. The transmission components and guide rails are equipped with well-protected protective covers and warning signs to avoid equipment damage caused by accidental injury and foreign body falling.

8. Man-machine interface is easy to use and friendly. The operator only needs to select the preset processing parameter table according to the glass thickness, load the piece, and start the equipment, and the processing process does not require human intervention.

Equipment parameters:

Models: DC2504, DC2004, DC1604

Application: rectangular float glass coarse ground chamfering and film removal optional bottom

Grinding head configuration: 4 grinding head sets, each grinding wheel set configuration: upper/lower chamfered diamond wheel 2 (optional chamfered resin wheel) + bottom edge diamond wheel 3

Processing range (length optional) : 300*650 ~ 2440*3000mm, 350*600 ~ 2000*3000mm, 350*600 ~ 1600*2500mm

Machined thickness: 4-12mm (standard for 4-8mm grinding wheel, optional 6-12mm)

Glass error before processing: glass length and width error ±2mm (does not correct the glass error, the larger error will affect the grinding quality and consistency)

Chamfering size: (according to the length of the bevel) 0.5-2mm

Bottom grinding amount: 0.1 ~ 0.3mm on one side (trimming bevel, 4-8mm glass can not leave grinding amount)

Glass yield: ≥98%

Grinding speed: chamfering 12-40m/min

Processing efficiency: 6p/min (calculated by 4*1000*1000mm glass without obvious defects)

Air source: 0.6Mpa ~ 0.8Mpa, Φ10,

Water consumption: Change circulating water and refill water per shift, 0.5 cubic meters

Working face height: 900 ~ 960mm

The maximum dimensions (L x W x H) of the equipment: 7150 x 4500 x 2150mm, 7150 x 4000 x 2150mm, 6450 x 3600 x 2150mm

Weight: 5.5t, 23 Φ80 pedestal plates, 5t, 4.3t

Installed power: 24kW, three-phase four-wire, 380V/50Hz, 23kW