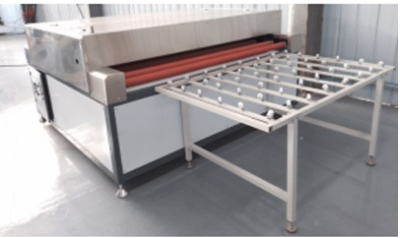

3826 Glass Cutting and Loading All-In-One Machine

1. It offers fully automatic cutting and processing for straight-line or irregular shapes based on user requirements.

2. Cutting pressure is entirely computer-controlled, resulting in high-quality cutting.

3. The work surface is equipped with air flotation and adjustable height to meet specific needs, ensuring excellent performance, safety, and reliability.

Equipment features:

1. Fully automatic cutting and processing for straight or irregular shapes according to user requirements. Direct input of glass dimensions for cutting, real-time display of cutting patterns, and actual movement tracking for clear monitoring of equipment and processing conditions.

2. Cutting pressure is entirely computer-controlled, ensuring high cutting quality.

3. Rack and pinion components use high-quality products from internationally renowned brands, guaranteeing cutting precision, speed, and accuracy.

4. Axis drive employs imported servo motors for high repeatability in cutting origin positioning.

5. Imported optimization software with powerful nesting functions, user-friendly interface, easy learning curve, and convenient operation.

6. Equipped with comprehensive safety measures to ensure prolonged equipment operation.

7. Comes with a double-sided dual-workstation or single-sided single-workstation upper sheet platform, featuring gear drive for safety and reliability.

8. Equipped with a breaking platform for easy operation with one key start.

Main parameters:

Power consumption | 380V 50HZ 8KW |

Maximum processing size | 2600*3660mm |

Upper sheet thickness | 3-19mm |

Maximum suction depth | 450mm |

Number of suction cups on a single arm | 4 |

Compressed air | 0.6Mpa |

Working table height | 900±50mm |

Cutting thickness | 3-9mm |