Company News

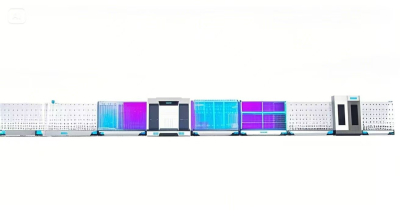

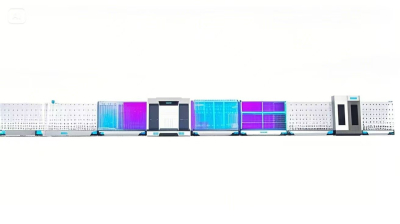

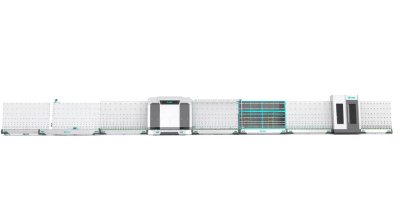

In response to the market demand for efficient and intelligent insulating glass production equipment, Shandong Mingshengyuan has officially launched a new automatic insulating glass aeration production line with years of technological precipitation and R&D innovation in the field of glass deep

2025/03/24 14:17

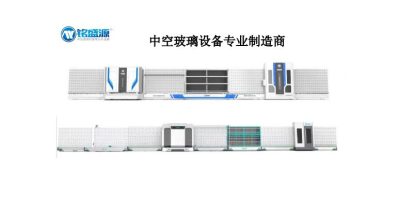

In the current construction and industrial fields, insulating glass has become the darling of the market with its excellent sound insulation and thermal insulation performance. The insulating glass equipment of Shandong Mingshengyuan is standing at the forefront of promoting the progress of the

2025/03/21 13:56

In today's era of vigorous development of the construction industry, insulating glass with its excellent thermal insulation and sound insulation performance, has become a key material for building energy conservation, and the technical level and production efficiency of insulating glass equipment

2025/03/18 13:22

At present, an industry event is being warmly carried out in Moscow, Russia, Shandong Mingshengyuan Gargle Equipment Co., Ltd. under the leadership of Manager Jia and Manager Zhou, with a sales team. At the exhibition site, the crowd in front of the booth of Shandong Mingshengyuan was bustling and

2025/03/13 11:15

The use of automatic insulating glass equipment has many benefits, mainly reflected in the following aspects:1. Production efficiency improvementA. Automatic continuous operation: it can automatically complete A series of processes such as loading, cleaning, gluing, gluing, pressing, etc., without

2025/03/10 09:40

Recently, the insulating glass equipment industry ushered in a major breakthrough, Shandong Mingshengyuan successfully developed a new generation of automatic insulating glass production line, with its excellent performance and innovative technology, to inject new impetus into the field of building

2025/03/04 09:34

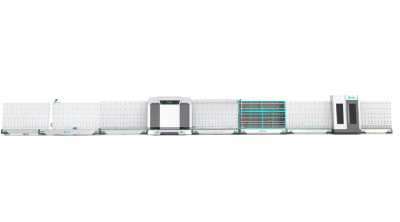

Automatic insulating glass equipment has a variety of excellent performance, the following are some main aspects:1. Efficient production performancea. High degree of automation: the insulating glass production line can automatically complete multiple processes of insulating glass production, such

2025/02/25 13:30

The use of automatic insulating glass glue machine need to pay attention to the following matters:1. Temperature: The construction temperature of insulating glass sealing wire is usually between 5-40°, and the construction temperature below 5° or above 40° should be avoided as far as possible,

2025/02/17 13:52

Precautions before using insulating glass equipment include the following :1. Check the equipment status : before operating the insulating glass production line, it is necessary to conduct a comprehensive inspection of the equipment to ensure that the equipment is placed in a horizontal

2025/02/11 15:34

Insulating glass production line operating procedures of the main steps and precautions1. Preparation :① Open the total power supply and air source of the insulating glass production line.② The water tank of the cleaning machine is filled with water, and the water heater is turned on in winter

2025/01/14 13:43

1. Glass cleaningCleaning glass is the first link in the production of insulating glass, and it is also one of the most important links to ensure the sealing of insulating glass. If the stain on the glass can not be thoroughly cleaned off, the adhesive force of the sealant on the glass will be

2025/01/10 13:48

The impact of automatic insulating glass production line on the door and window industry is mainly reflected in improving production efficiency, reducing costs, improving product quality and promoting the sustainable development of the industry. Firstly, automatic insulating glass production

2025/01/02 13:48